Flexographic Printing Machine (Roll to Roll)

TKNRP-20126C

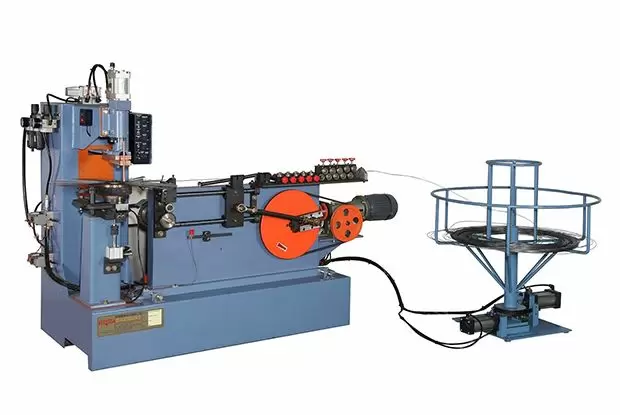

Flexographic Reel to Reel Printing Line, Roll to Roll Flexographic Printing Press is for printing colors on PP woven bag.

Our Flexographic Printing Machine (roll to roll) has high production performance for printing colors on PP woven fabric roll. The whole machine includes Un-Winding Section, Printing Section, Drying System, Re-Winding Section and other auxiliary equipment.

Features

- It’s available for printing two sides on the PP woven fabric roll in one time.

- The printing registration system is the latest design for online adjustment while machine is running. It means no need to stop the machine for printing registration.

- The Air Sucking Blower is specially for raising drying efficiency (for quick drying).

- The Blowing Blade (Blowing Pipe Type) is designed for quick drying.

- The operating system is more humanized and instinctive touch panel becomes easier to use.

- The safety covers and emergency stop device help to avoid or reduce injury and damage.

Specification

| Description | Specification |

|---|---|

| Diameter of Unwinding Cloth | 1200 mm (Max.) |

| Processing Tube Width | 350 - 850 mm (Max.) |

| Printing Width | 840 mm (Max.) |

| Printing Repeat Length | 500 – 1350 mm |

| Production Output | Max. 80 - 120 M/min. |

| Un-Winding Section | |

| Fabric Roll Lifting | Pneumatic Type |

| Auto Edge Position Control (EPC) | Hydraulic type, with 1 HP AC motor |

| Tension Control | Powder Brake Tension Control |

| Air Shaft | 1 pc (bobbin inner diameter is 3" as standard size) |

| Printing Section | |

| No. of Color | 6 colors |

| Printing Method | 6+0, 5+1, 4+2, 3+3 |

| Adjustment of Printing Position | Horizontal or vertical position is adjustable |

| Printing Roller Elevator Hydraulic Unit | 2HP AC Motor |

| Ink Roller Non-Stop Motor | AC 1/8 HP Reducer Motor x 6 |

| Printing Roller Hoiser | 1/4 AC Motor x 1, 1 HP AC Motor x 1 |

| Main Driving Motor | 7.5 HP AC Motor + Inverter |

| Drying System | |

| Thermal Air Blower with Heater | Heater: 800W x 9 pcs Blower: 3HP |

| Air-Suction Blower | 3 HP Blower |

| Re-Winding | |

| Winding Method | Surface Friction Type. |

| Winding Motor | 3 HP AC Motor with Inverter Control |

| Power Consumption | |

| Rated Power Capacity | 30 KW |

| Actual Power Consumption | 12 - 22 KW |

| Dimension (L x W x H) | 12,600 x 2,250 x 3,150 mm |

| Weight | 21,000 kg |

- Photo Gallery

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Flexographic Printing Machine (Roll to Roll)

- Un-Winding Section

- Un-Winding Section

- Printing Section

- Printing Section

- Printing Section

- Re-Winding Section

- Re-Winding Section

- Movies

- Files Download

Flexographic Printing Machine (Roll to Roll) - TKNRP-20126C | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including Flexographic Printing Machine (Roll to Roll), PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

(1).jpg?v=11c6f2b2)

(2).jpg?v=3b16f329)

(3).jpg?v=a682b442)

(4).jpg?v=a4471be4)

(5).jpg?v=b0f5182e)

(6).jpg?v=7986c14e)

(7).jpg?v=6a66875b)

.jpg?v=b86e451f)

.jpg?v=b701f658)

.jpg?v=53f5ecd9)

.jpg?v=ba50947c)

.jpg?v=dd42079f)

.jpg?v=50f86d16)

.jpg?v=55344f8c)