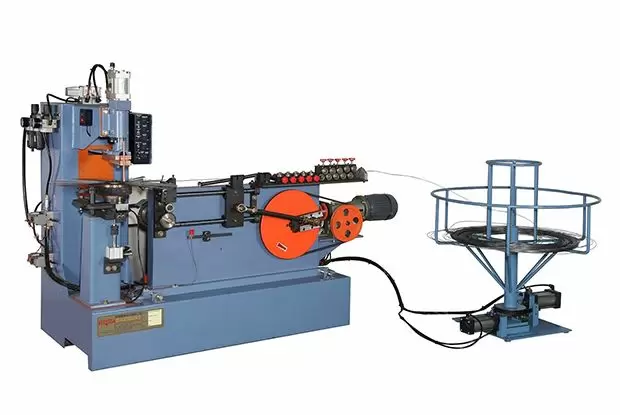

Plastic Powder Waste Recycling Machine (Die-Face Cut with Force-Feeding)

TK-150i

Plastic Pelletizer, Plastic Pelletizing Machine, Plastic Granulator, Plastic Recycling Extruder

Plastic waste recycling machine (die-face cut with force-feeding) is suitable for recycling plastic powder waste, such as HDPE, LDPE, LLDPE PP, PS to produce high quality plastic pellets. These plastic pellets can be used for new plastic products.

In general, suitable model would be dependent on the material for recycling and your purpose. So, for quotation, it's better to show us some pictures of your plastic waste and ideal output (kg / hr.) first, and we can figure out suitable solution for you.

Features

- Special design working plastic powder.

- Low cost and high profit

- Material feeding efficiency

- High output

Specification

Model: TK-150i

For HDPE powder waste, capacity: 420~500 kg/hr.

For LDPE powder waste, capacity: 450~550 kg/hr.

For PP/PS powder waste, capacity: 430~500 kg/hr.

| Item No. | Description | Specification |

|---|---|---|

| A. | O-Type Screw Conveyor | 1 set |

| 1. | Motor | 5 HP + Inverter + Reducer |

| 2. | Dimension | Φ10” × 5000L |

| 3. | Feeding Entrance | 1000 × 1000 mm (with Anti-Crosslinkage Device) |

| B. | Hopper with Force-Feeding Screw | 1 set |

| 1. | Hopper | SUS#304, Capacity: 100 kg, with cover |

| 2. | Force-Feeding Motor | 7.5 HP + Inverter + Reducer |

| 3. | Feeding Screw | SNCM439 with Anti-Crosslinkage Device |

| C. | Main Extruder | 1 set |

| 1. | Main Motor | 175 HP + Inverter |

| 2. | Screw Diameter | Φ150 mm |

| 3. | Screw L/D | 36/1 |

| 4. | Screw Material | Bimetallic (material is Japan made and reprocessed in Taiwan), finished with 168 hr. of Gas Nitriding and polished. |

| 5. | Barrel Material | SACM645 (material is Japan made and reprocessed in Taiwan), finished with 168 hr. of gas Nitriding and polished. |

| 6. | Heater | SUS#304 |

| 7. | Ventilation Hole | Single |

| 8. | Barrel Cooling | By Air |

| 9. | Screen Changer | 1.Motor: 10 HP x 1 set |

| D. | Sub Extruder | 1 Set |

| 1. | Main Motor | 75 HP + Inverter |

| 2. | Screw Diameter | Φ165 mm |

| 3. | Screw L/D | 10/1 |

| 4. | Screw Material | SACM645 (material is Japan made and reprocessed in Taiwan), finished with 168 hr. of gas Nitriding and polished. |

| 5. | Barrel Material | SACM645 (material is Japan made and reprocessed in Taiwan), finished with 168 hr. of gas Nitriding and polished. |

| 6. | Heater | SUS#304 |

| 7. | Barrel Cooling | By Air |

| 8. | Screen Changer | 1.Screen Size: Φ300 mm x 2 2.Pressure Sensor: GEFRAN-Italy × 1 pc |

| E. | Hot Die-Face Cutting Device | 1 Set |

| 1. | Die-Face Material | SKD61 |

| 2. | Cutter Motor | 5 HP + Inverter |

| 3. | Pump Motor | 5 HP for Water Circulation |

| 4. | Cutting Blade | 3 pcs, Automatic adjusting |

| 5. | Water Jacket | SUS#304 |

| F. | Centrifugal Dryer | 1 Set |

| 1. | Motor | 7½ HP |

| 2. | Material | SUS#304 |

| 3. | Air Cyclone | SUS#304 |

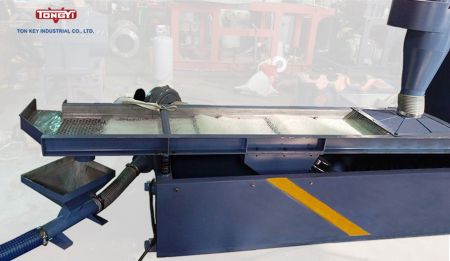

| G. | Vibration Screener | 1 Set |

| 1. | Motor | 1/3 HP x 2 |

| 2. | Screener Material | SUS#304 |

| 3. | Frame Material | SS41 |

| H. | Air Blower | 1 Set |

| 1. | Motor | 7½ HP |

| I. | Storage Silo | 1 Set |

| 1. | Silo Capacity | 1500L, its outlet design for packing 25kg, 500kg/1000kg |

| 2. | Silo Material | SUS#304 |

| 3. | Frame Material | SS41 |

- Photo Gallery

- Movies

- Files Download

Plastic Powder Waste Recycling Machine (Die-Face Cut with Force-Feeding) - Plastic Powder Waste Recycling Machine (Die-Face Cut with Force-Feeding) | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including Plastic Powder Waste Recycling Machine (Die-Face Cut with Force-Feeding), PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

.jpg?v=67964ffa)

.jpg?v=43ac2c7e)

.jpg?v=0c5aadba)