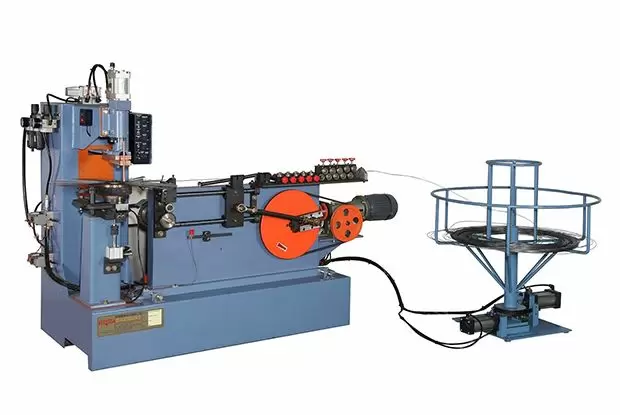

Warping Machine

V-TY-48Y

Warping Machine for PP Mat, Yarn Warping Machine, Warping Machine with cheese creel is for beaming warp yarn of PP mat weaving.

Warping Machine is warping yarn (polyester, multifilament yarn) setting machine in beam for producing PP mat.

Features

- Drum-driven System which is adjustable width for various weaving needs.

- Automatic Stop Device when warp yarn breaking.

- Two-step warping speed.

- Special width (48" up) of beaming is available upon request.

- Easy operation and maintenance.

- The machine is assembled by sturdy components that can last for long time under normal operation.

- Machine running is smoothly.

Specification

| Item No. | Description | Specification |

|---|---|---|

| 1. | Capacity | 2,000 - 2,400 M/hr |

| 2. | Motor | 3 Phase, 1 HP, 4 poles |

| 3. | N.W. | 1,010 kg |

| 4. | G.W. | 1,100 kg |

| 5. | Machine Size (cm) | 920 x 220 x 210 |

- Photo Gallery

- Movies

Warping Machine - Warping Machine | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including Warping Machine, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

.jpg?v=0bbfa9e2)