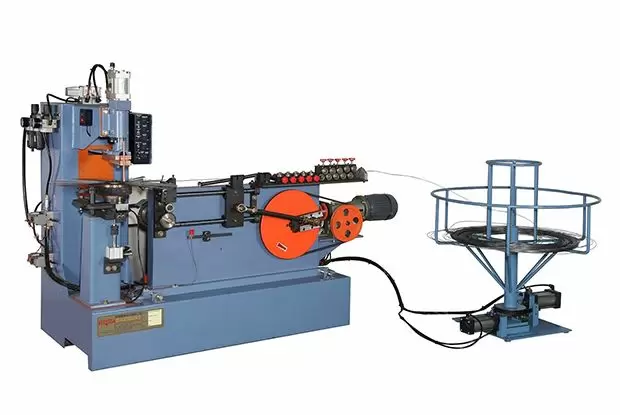

Butting Machine

CH-BF

Ring Butt Welding Machine

The function of Butting Machine is used to weld metal ends, so that the metal wire ends welded together perfectly.

It’s also used to welding the steel wire, steel ring, stainless steel, stove frame and home appliance.

Function Device

・Air Control Unit

・Cylinder

・Electrode Holder

・Tip

・Governor

・Foot Pedal Switch

・Welding Power

・Knife Switch

・Solenoid Valve

・Control Device

Specification

Fan Guard Making Machines - Butting Machine

Model: CH-BF

| Item No. | Description | Specification |

|---|---|---|

| 1. | Capacity | 35 KVA |

| 2. | Main Power Voltage | 1 Phase 440V |

| 3. | Controller Power Voltage | 1 Phase 220V |

| 4. | Welding Cylinder | Φ 50 |

| 5. | Welding Force | Max. 100 kg |

| 6. | Electrode | 16t x 44 x 48 mm |

| 7. | Cooling Method | Air Cooling |

| 8. | Power Line | Copper Wire 22 mm² 75A Breaker |

| 9. | Air Consumption | 15 L/min. |

| 10. | Produce | 3 sec./pc |

| 11. | Dimension | 90 x 60 x 105 cm |

| 12. | Weight | 230 kg |

- Photo Gallery

- Movies

- Files Download

Butting Machine - Butting Machine CH-BF | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including Butting Machine, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.