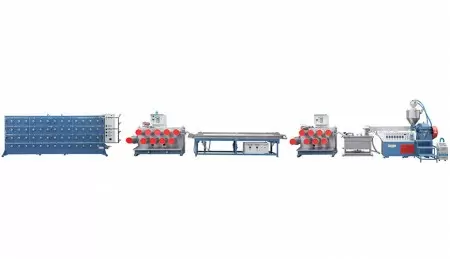

PE / PP Monofilament Making Machine

TK-75

PE / PP Rope Extrusion Machine

The extruding machine is designed for making PE or PE Monofilament Yarn (the material of the rope). There are two types of yarn, single yarn type and connected yarn type. The connected yarn is easier to operation and stronger. Our standard design is 6-connected yarn type, for other design is also available.

One extruder with 2 die, two dies could be different according to the need.

Special design for die to making connected yarn, after winding, is easy for next processing step.

Our standard type of winder is working with H type Plastic Bobbin S177. For other type of bobbins is also available.

Extruder is equipped accessories, including Auto Loader, Stair, Jack, and Air Compressor.

Please give us sample to show us the yarn type and let us know the bobbin size, if you have especial requirements.

Features

- Yarn Type: 6-connected yarn

- Bobbin: S177 (Plastic)

- Output: Max. 75 kg/hour

- Diameter of Monofilament: 0.1 - 1.00 mm

- ** Other design could be according to customer's requirement.

Specification

Output: Max. 75 kg/hour

Diameter of Monofilament: 0.1 - 1.00 mm

HDPE: Yarn Φ 0.24-388 D Speed: 120 m/minute ⇒ 62.07 kg/hour

| Item No. | Description | Specification |

|---|---|---|

| A. | Extruder | |

| 1. | Screw Diameter | Φ 75 m/m |

| 2. | L/D | 28:1 |

| 3. | Motor | TECO 30HP + Inverter(30HP) / Micro-Computer Program Controls |

| 4. | Micro-Computer Program Control | |

| 5. | The Thermometer Auto-thermo Control | 7 Points SSR Control and LED Display |

| 6. | Jack | 1 pc |

| 7. | Stairs | 1 pc |

| 8. | Automatic Loader | 1 pc |

| B. | Cooling Tank | 1 set |

| 1. | Dimension | L 1200 m/m x W 450 m/m x H 560 m/m |

| 2. | Material | Stainless Steel |

| C. | Take-off Unit A | 1 set (Roller: 8 pcs) |

| 1. | Motor | TECO 7.5 HP + Inverter(7.5HP) |

| 2. | Roll Dia. | Φ 270 m/m x L 500 m/m |

| 3. | Hard-chrome Plated Stainless Steel Roller | 4 pcs |

| 4. | Rubber Roller | 4 pcs |

| 5. | Press Roller | 1 pc (Manual Type) |

| 6. | Line Speed Display | |

| D. | Hot Water Tank | 1 set |

| 1. | Size | L 4000 m/m x W 440 m/m |

| 2. | Material | Stainless steel |

| 3. | Micro-Computer Program Control | |

| 4. | The Thermometer Auto-thermo Control | 2 Points SSR Control and LED Display |

| 5. | Air Compressor | 1 HP |

| 6. | Air Cylinder | 2 sets |

| E. | Take-off Unit B | 1 set (Roller: 10 pcs) |

| 1. | Motor | TECO 15HP + Inverter(15HP) |

| 2. | Roll Dia. | Φ 270 m/m x L 500 m/m |

| 3. | Hard-chrome Plated Stainless Steel Roller | 10 pcs |

| 4. | Press Roller | 1 pc (Manual Type) |

| 5. | Line Speed Display | |

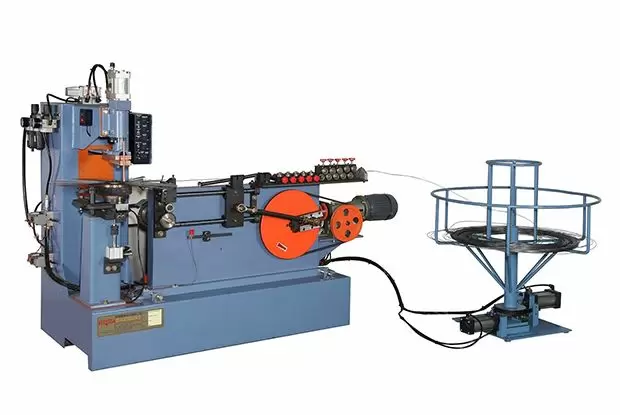

| F. | Winding Machine (H Type) | 1 set |

| 1. | Number of Spindle | 52 Spindles |

| 2. | Traverse Motor | 2 HP |

| 3. | Winding Motor | 3 kg-cm |

- Movies

- Files Download

PE / PP Monofilament Making Machine - PE / PP Monofilament Making Machine Mode, TK-75, Bobbin S177 | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including PE / PP Monofilament Making Machine, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.