PP⁄PS Sheet Making Machine

TK-100HIP

PP⁄PS Sheet Extruder

PP/PS sheet making machine is suitable for processing PP⁄PS pellets or raw material to produce high quality plastic sheet films.

These plastic sheet films for widely used in plastic container packaging such as plastic lunch box, plastic fruit and vegetable container, disposable plates, plastic cups, disposable salad bowls, disposable tureens, disposable saucers...

Specification

MODEL:TK-100HIP

Finished product: PP Sheet

Width of sheet: 650 -830 mm

Thickness of sheet: 0.3 -1.5 mm

Output capacity: PP - 200~250 kg/hr.

Line Speed: ~ 35 m/min

| Item No. | Description | Specification |

|---|---|---|

| A. | Horizontal Mixer | |

| 1. | Capacity | 500 kg |

| 2. | Driving Motor | 5 HP |

| 3. | Plastic Contact Surface | SUS304 |

| B. | Auto Loader | |

| 1. | Driving Motor | 3 HP |

| C. | Ø 100 mm Extruder | |

| 1. | Use High-Speed Gear Box | |

| 2. | Screw Diameter | Ø 100 mm |

| 3. | Screw Length Ratio (L/D) | 30/1 |

| 4. | Screw Rotation Speed | 0 - 120 RPM |

| 5. | Driving Motor | 150 HP + Inverter |

| 6. | Barrel Material | Special alloy steel imported from JAPAN: SACM-645. Hardness can reach to 68 –70 HRC° (HV940 – 1076) |

| 7. | Screw Material | SACM-645. Use nitrous processing. Hardness can reach to 68 –70 HRC° (HV940 – 1076) |

| 8. | Barrel Temperature Controller and Heater | 6 zones, Heating Capacity: about 30 kw |

| 9. | Cooling System for Barrel | Blower, 6 zones |

| D. | Hydraulic Screen Changer | |

| 1. | Type | Sliding Plate Hydraulic Screen Changer |

| 2. | Hydraulic Unit | 3 HP |

| 3. | Auto-Thermo Controller | 1 zone, Heating Capacity: about 4 kw |

| 4. | Adapter Temperature Controller | 1 zone, Heating Capacity: about 1 kw |

| E. | Polymer Melt Metering Pump | |

| 1. | Model | TK-56/56 |

| 2. | Motor | 10 HP + Inverter |

| F. | Pressure Gauges | 3 sets (Brand: GEFRAN, Italy) |

| 1. | One Set Is In Front Of Screen Changer | |

| 2. | One Set Is In Front Of Gear Pump To Control Screw's Rotational Speed | |

| 3. | The Other One Is In Front Of T-Die To Reveal Pressure and Temperature | |

| G. | T Die | |

| 1. | Width of T Die | 1000 mm |

| 2. | Heating Capacity | 24 kw |

| 3. | T Die Temperature Controller | 5 zones |

| 4. | Lip Width Adjustable | |

| H. | Horizontal Forming Roller | |

| 1. | Forming Rollers | Polishing Roller,φ280 × 1000 mm x 1pc |

| 2. | Hydraulic Control Open/Close Unit | 1 pc |

| 3. | The Distance Between Rollers Adjusted By Hydraulic Rollers' Up & Down, Forth & Back Controlled By Electric Adjustment | |

| 4. | Hardness of Rollers | HRC 50° |

| 5. | Surface | Polishing Process RA 0.01μm |

| 6. | Each Roller Has A Servo Motor. | 4 kw x 3 pcs |

| 7. | Rollers can chill themselves by hot water and control their own temperature separately/temperature controller. | Mold Temperature: 3 sets; |

| I. | Extending Rollers | |

| 1. | Size | φ175 × 1000 mm × 1 set (2 pcs) |

| 2. | Extending Motor | Servo Motor 4 kw* 1 pc |

| 3. | Side-Material Trimming Unit | Knife type, Each Knife for Both Sides |

| J. | Edge Trim Recycling | |

| 1. | Crusher | 1 set |

| 2. | Driving Motor | 5 HP |

| 3. | Conveyer and Collection Baller | 3 HP |

| 4. | Cyclone | φ300 |

| 5. | Screw Feeder Equipment | 1 HP |

| K. | Winding Machine | |

| 1. | Driving Motor | 1 HP |

| 2. | Winding Bobbin | 2 pcs |

| 3. | Winding Motor | 0.75 kg/m |

| 4. | Wind-Up Size | φ850 x 1000L mm |

| L. | Inverter Control Box | 1 set |

| M. | Temperature Control Box | 1 set |

| O. | Operation Control Box (Human Machine Interface) | 1 set |

- Photo Gallery

- Horizontal Mixer

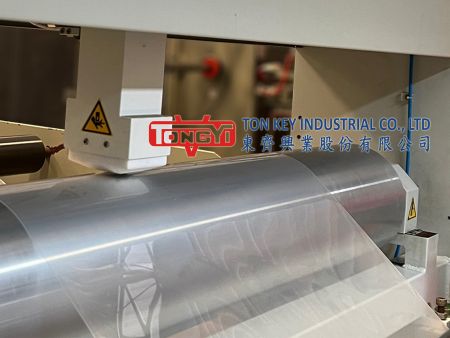

- PP⁄PS Sheet Making Machine

- Feeding_Hopper

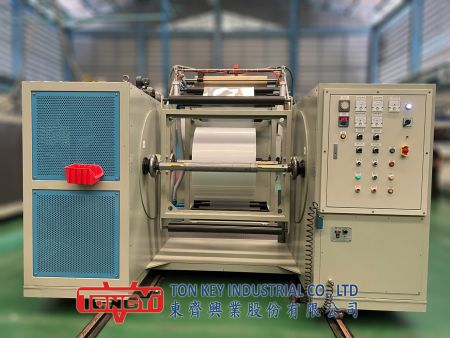

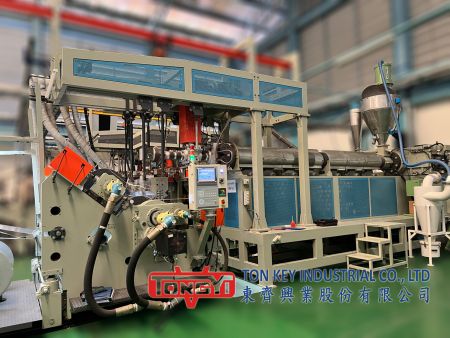

- Extruder + T-Die + Horizontal Forming Roller Unit

- Control Panel

- PP⁄PS Sheet Making Machine

- PP⁄PS Sheet Making Machine

- Side Trim Winder + Thickness Measurement System + Taking Rollers

- Thickness Measurement System

- Release Agent Application Unit + Winding Machine

- Winding Machine

- Movies

PP⁄PS Sheet Making Machine - PP⁄PS Sheet Making Machine | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including PP⁄PS Sheet Making Machine, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

_202404.jpg?v=f91f99bc)

_202404.jpg?v=50fefebf)

_202404.jpg?v=91e0188d)